|

Guotai Vacuum Equipment Co.,Ltd

|

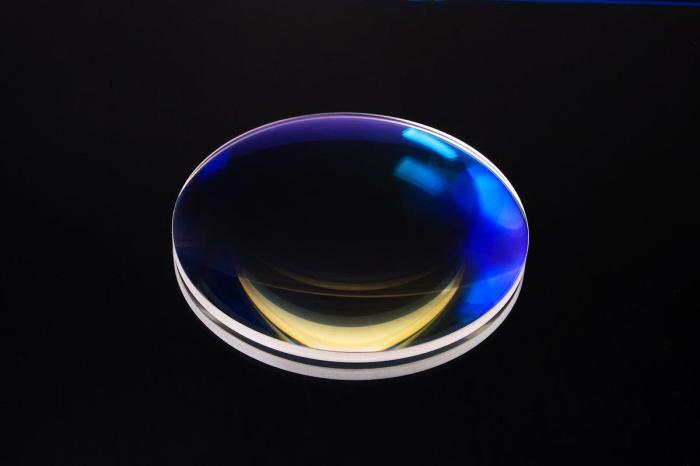

Glass Lens Vacuum Coating System

| Price: | 800000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Optical coating Machine is equipped with a quartz crystal thickness meter

2. PLC and touch screen systems operation.

3.Applies to optics industry

Glass Lens Electron Beam Evaporation Coating Machine

Optical coating machine working principles:Electron beam evaporation is that the membrane is put into the water-cooled copper crucible, heated by direct use of electron beam, the vaporized atoms or molecules of membrane material is condensed to a mould by incidence to the surface of the substrate after escaping from the surface evaporation. Electron beam evaporation has high thermal efficiency, beam density, evaporation speed, high purity of film made than the resistance heating evaporation.

Introduction:

This

equipment is designed for precision optical thin film coating

production,system unit and overall structure good to meet the

requirements of the optical thin film production process,suitable for

coating anti-reflection film, bandpass membrane,cut off film and other

coating film system.It is equipped with high-precision film thickness

control system,excellent performance of electron gun,high degree

automation of coating control system, etc. It's the ideal of high

precision optical thin film plating equipment.

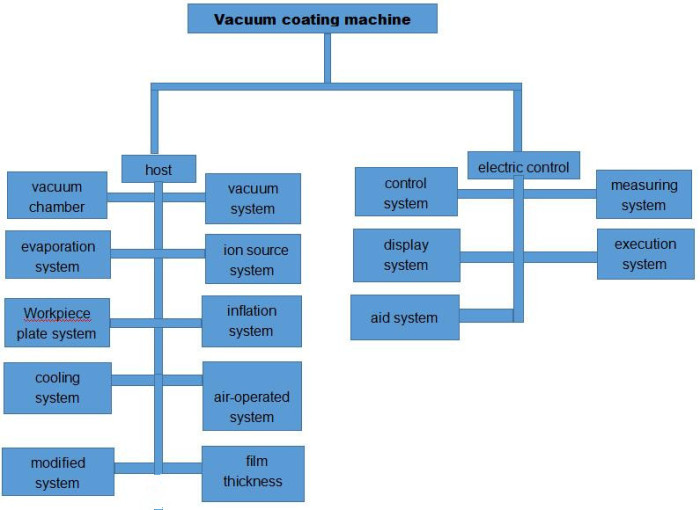

Equipment structure:

Features:

Fully integrated in the machine control platform.

Fully automated coating process and control.

High speed coating process.

Stable productivity and uniformity

Easy job and process set-up and maintenance.

User-friendly control software.

Item | Optical Coating Machine |

Dimension | Custom made |

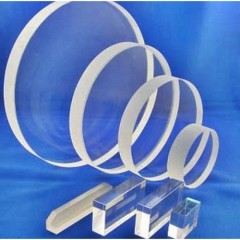

Substrate dome Size | Custom made |

Vacuum chamber Structure | Cabinet type single door , 304 stainless steel material |

Ultimate vacuum | 3×10-4Pa |

Restore vacuum | 4×10-3Pa,≤12 minutes |

Vacuum pumping system | Mechanical pump, roots pump,diffusion pump, molecular pump,Polycold etc,according to technological requirements |

Substrate dome structure | Three or four fan,ball,custom made |

Substrate dome rotation speed | 3~30 r.p.m |

Baking structure | Up barrel heating, down radiation heating |

Heating material | Tubular heaters, iodine tungsten lamp |

Control mode | Touch Screen,PLC,Manual and Automatic |

Temperature | 350℃ |

Temperature uniformity | 350℃ ± 10 ℃ |

Evaporation source | Resistance evaporation source, electron beam evaporation source. |

Working environment requirements

| 1. Environment temperature:10~35℃ 2 .Relative humidity: no more than 80% |

Equipment power requirements | Water source: industrial water softening or circulation water. Water pressure: 0.15 ~ 0.25 Mpa, Water inflow temperature:≤25℃; Gas source:pressure 0.6MPa Power supply: three-phase, 220 V / 380 V, 50 HZ |

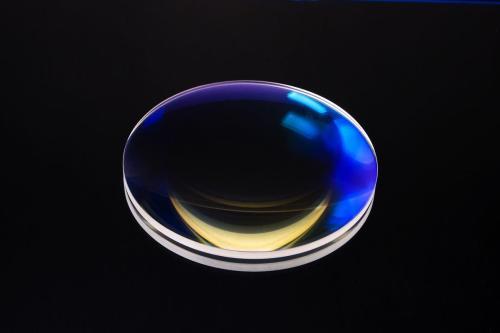

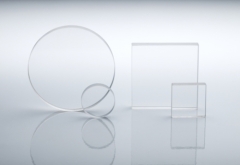

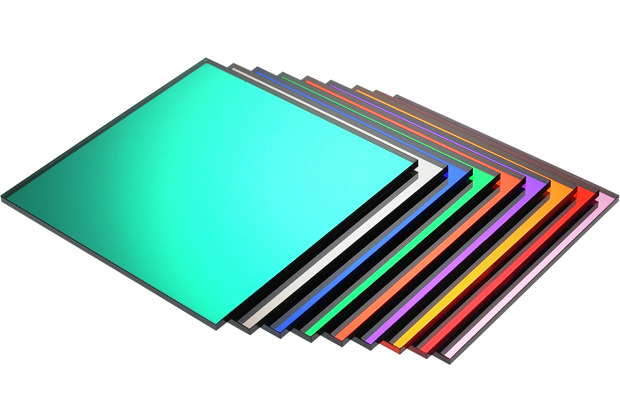

Application:

Optical Coating Machine widely used in antireflection film, reflective film, filter membrane, beam splitter, band-pass film, dielectric film, highly reflective film, reflective film of various color film system ,automotive reflective glass, glasses, optical lens,etc.

Advantages:

1.Rich

experience in Optical coating industry, we design and manufacture

optical coating machine to meet your process requirements.

2.Undertaking a variety of optical coating services.

3.About 2 months production time.

4.One year warranty, life-long maintenance

5.Wearing spare parts for free.

6.Provide door-to-door installation services,

7.Wooden package

8.T/T,Western Union payment available

9.Convenient transportation and timely delivery.

We are factory ,with rich experience in design and manufacture optical coating machine,also,we can undertake optical coating service.Show me your products,Chengdu Guotai will give you a solution to meet your coating requirements.

Workshop show

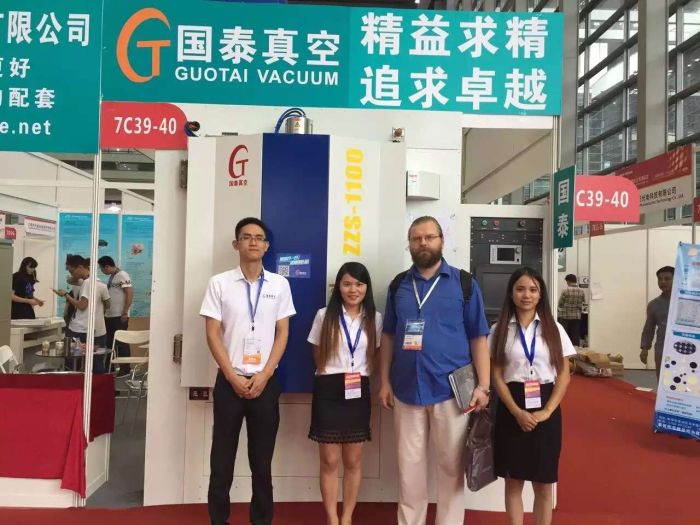

Our team

Customer visit

Exhibition

Certification

Package show

Note:

1.We have more optical vacuum coating machine models,such as ZZS500,ZZS630,ZZS800,ZZS900,ZZS1100,ZZS1300,ZZS1600,ZZS1800,ZZS2000,ZZS2350.

2.Equipment final size and configuration customized production according to your requirements.