|

Guotai Vacuum Equipment Co.,Ltd

|

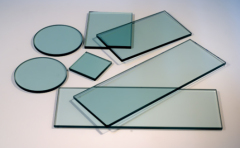

Evaporation coating machine for coating ceramic / jewelry / plastic / aluminum

| Price: | 80000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1, front vertical door

2,304stainless steel

3,high quality and reasonable price

4,welcome to our factory to visit

Evaporation coating machine for coating ceramic / jewelry / plastic / aluminum

Vacuum chamber:

vacuum chamber consists of cabinet and door to meet the rotating of roundness workpiece plate. The door and the chamber is connected by a hinge and use "O" type rubber ring to seal, the sealing pressure mainly rely on the atmospheric pressure above the door, the pre-pressure is generated by the combination of the upper, lower cylinder on the right side of door and hinge. There are several φ33.5mm holes at the upper and lower chamber plate which can be the port of electrode, the inflator, high voltage, water ,baking, etc., it also can be used to introduce other connectors. There are open roundness holes on the chamber which is convenient to install modifying mask and the rear part of the chamber connect with the high valve as a whole, also there are rectangular water pipe on the surface of chamber, large assembly lugs on the top. Needed seal groove on the door frame has been processed and prepare screw holes for installing hinge. At the same time there are rectangular water pipe on the door and observation windows diameter is Φ125mm which can observant the working condition of evaporation source and the coating of workpiece plate .

Resistance evaporation source:

Usually three water-cooled electrodes can be installed in two evaporation boats. A set of power supply for public using which connect separately by one shift switch, alternately evaporate (can be controlled independently).it can adopt the structure of 4 water-cooled electrodes erection joint.

Electron beam evaporation source:

Single gun is equipped with one set of power supply, one operational hand-held remote control box. Two guns are equipped one set of power supply, two operational hand-held remote control boxes.

Workpiece driving device:

It consists of gear motor outside of the door, synchronous belt, magnetic fluid, the gear at the top of vacuum chamber ,workpiece holder and other components .The transmission of gear motor drive the synchronous pulley outside of the magnetic fluid through reducer, then achieve the revolution of workpiece through the gear engagement inside of magnetic fluid . Gear motor can stepless speed regulation. The device can be installed flat workpiece plate, spherical workpiece plate, planetary workpiece plate, fan workpiece plate, other forms of workpiece plate and the interchange is very convenient.

Workpiece baking device:

There are upper baking and lower baking and upper baking use tubular heater, the highest baking temperature up to 350 ℃, tubular heaters arranged evenly and multiple temperature control, each heating wire has a K- type thermocouple to test temperature. Heating wire connector is water cooling structure ,if the baking cannot open, the whole heating zone can be controlled and adjustable. Lower baking is iodine-tungsten lamp heating, its heating fast.

Baffle structure:

It close to evaporation source which is used to shield the impurities and dirty evaporation material when pre-melting and to shield the evaporation material when get the required film thickness to ensure the purity and thickness. The specific height and the distance to the evaporation source can be adjusted. Baffle is pneumatic rotation structure. Sometimes one baffle can be used by resistance steaming and electron gun evaporation source at same time.

Vacuum measurement socket:

It is placed behind the chamber and can be installed in different vacuum measuring tube which is national standard opening size, easy to install required vacuum regulation.

Chamber deflation valve

It is placed behind the chamber for deflating the gas. There is silencer at the deflation gas port(silencer is leaded in the clean-room) to prevent the dust is sucked in the chamber and there are two different diameter deflation valve(One group can be adjustable)to realize the requirements of fast or slow.

Chamber lighting

Low power bromine tungsten lamp for evaporation room lighting which installation position can be moved.

Hold-down mechanism

Be installed on the door of the chamber . when close the door ,the cylinder running. Drive the rotating wheel to compress the door.

Parts of the machine

Application:Optical coating machine used for coating Anti-Reflection ,Beamsplitter ,Peppers Ghost Effect,Teleprompter /Prompting Mirrors,Dielectric Mirrors,Fibre Optic Coatings,Front Surface Mirror,Large Area Dielectric Beamsplitters,Large Front Surface Mirrors ,Metal Coatings,Neutral Density Filters,RFI shielding, Anti-static and Heated Window Coatings,Unbreakable Plastic Mirrors,UV Mirror Coatings,Telescope Mirror Coating / Re-coating.

Company introduction:

Chengdu Guotai Vacuum Equipment Co.,Ltd is a large vacuum coating equipment company ,which is collection of research & development ,production,marketing,and after-sales service of integrated.

We are focus on manufacturing Optical Vacuum Coating Equipment,Winding Vacuum Coating Equipment,Continuous Coating Production Line,Magnetron Sputtering Vacuum Coating Machine,Vacuum Electric,Vacuum Parts and Consumables etc.Machine produces film which widely used in electro-optical system and thin film instruments,such as digital cameras,digital video,binoculars,projector,energy control,optical communication,display technology,interferometer,satellite missiles,semiconductor laser,mems,information industry,laser production,various kinds of filter,lighting industry,sensors,architectural glass,automotive industry,decoration,glass lens,metal,resin,ceramic,etc.Good quality products and excellent after-sales service make company market share increasing by 35% per year.Except sale equipment ,we also undertake a variety of optical coating services.

We

adhere to honesty,quality first as spiritual

idea,innovation,dedication,harmony and win-win as principle,provide high

quality products and excellent service to each customers.Chengdu Guotai

Welcome your come.

Workshop show

Our team

Customer visit

Exhibition

Certification

Package show

Note:

1.We have more optical vacuum coating machine models,such as ZZS500,ZZS630,ZZS800,ZZS900,ZZS1100,ZZS1300,ZZS1600,ZZS1800,ZZS2000,ZZS2350.

2.Equipment final size and configuration customized production according to your requirements,we also undertake all kinds of optical coating film service.

What we can do more for you :

1.One year guarantee period ,life-long maintenance.During warranty period free replacement parts.

2.The

whole electric control manufactured by us, including vacuum gauge and

pressure control instrument,etc.Once there are problems,we will be free

to provide them to you to replace ,make sure decrease your lose during

equipment downtime.

3.Free training for operation and maintenance

personnel,provide detailed equipment maintenance materials,include

consumables parts number and contact way,to make sure customers can

independently replace vacuumpump,regular system maintenance,when

necessary.

4.If fault occurs during equipment use process,we will

respond within 24 hours,If due to manufacturing reasons,we will bear

responsibility.

5.We will keep long-term tracking ,when upgrading

products we will provide cost price replacement , to make equipment

achieve better performance,to realize our compromise of equipment

further improve and perfect .

6.We can make relative adjustment according to your special requirements .

Please feel free to contact me :

Contact person:Alice

Skype / Wechat:alice2013681

WhatsApp:+8613408484278

Phone: +8628-82666357, +8628-82666563

Fax:+8628-82666193

Mobile Number:+8613408484278

Email:optical.coatingdevice@yahoo.com

Facebook:852569632@qq.com

Follow me on twitter: https://twitter.com/opticalcoating1

Web:http://www.gtvacuum.com / www.cdguotai.com