|

Guotai Vacuum Equipment Co.,Ltd

|

Anti Reflective & Telescope Thin Film Coatings Machine Precision Optical Coating Solution

| Price: | 800000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Production time about 2 months.

2.Evaporation source:Resistance evaporation+Electron gun

3.Substrate heater:350 degree.

4.Optical coating service

Anti Reflective & Telescope Thin Film Coatings Machine Precision Optical Coating Solution

Working principle:ZZS series vacuum coating machine adopt electron gun bombardment materials evaporation technology for work-piece coating ,in order to change workpiece surface performance and get required coating products.

Introduction:

This

equipment is designed for precision optical thin film coating

production,system unit and overall structure good to meet the

requirements of the optical thin film production process,suitable for

coating anti-reflection film, bandpass membrane,cut off film and other

coating film system.It is equipped with high-precision film thickness

control system,excellent performance of electron gun,high degree

automation of coating control system, etc. It's the ideal of high

precision optical thin film plating equipment.

Specification

Model | ZZS660 Optical Coating Machine |

Dimension | Φ660mm×H800mm |

Substrate dome Size | Φ630mm |

Vacuum chamber Structure | Cabinet type single door , 304 stainless steel material |

Ultimate vacuum | 3×10-4Pa |

Restore vacuum | 4×10-3Pa,≤12 minutes |

Vacuum pumping system | Mechanical pump+ diffusion pump |

Substrate dome structure | Three or four fan,ball,custom made |

Substrate dome rotation speed | 3~30 r.p.m |

Baking structure | Up barrel heating, down radiation heating |

Heating material | Tubular heaters, iodine tungsten lamp |

Control mode | Touch Screen,PLC,Manual and Automatic |

Temperature | 350℃ |

Temperature uniformity | 350℃ ± 10 ℃ |

Evaporation source | Resistance evaporation source, electron beam evaporation source. |

Working environment requirements

| 1. Environment temperature:10~35℃ 2 .Relative humidity: no more than 80% |

Equipment power requirements | Water source: industrial water softening or circulation water. Water pressure: 0.15 ~ 0.25 Mpa, Water inflow temperature:≤25℃; Gas source:pressure 0.6MPa Power supply: three-phase, 220 V / 380 V, 50 HZ |

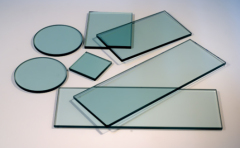

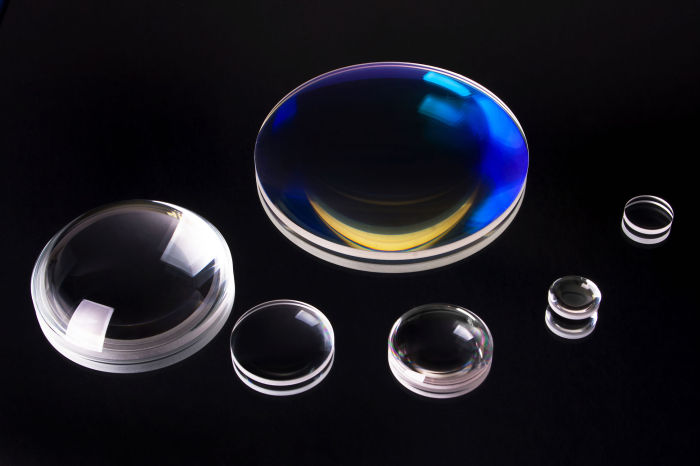

Application: widely used in front and back surface mirrors, dichroic filters, band pass color

filters, Anti-Reflective (AR), beam splitters, metal coatings, precision

hot mirrors, cold mirrors, neutral density filters, and IR and UV

filters.

Advantages:

1.Rich

experience in Optical coating industry, we design and manufacture

optical coating machine to meet your process requirements.

2.Undertaking a variety of optical coating services.

3.About 2 months production time.

4.One year warranty, life-long maintenance

5.Wearing spare parts for free.

6.Provide door-to-door installation services,

7.Wooden package

8.T/T,Western Union payment available

9.Convenient transportation and timely delivery.

We are factory ,with rich experience in design and manufacture optical coating machine,also,we can undertake optical coating service.Show me your products,Chengdu Guotai will give you a solution to meet your coating requirements.

Workshop show

Our team

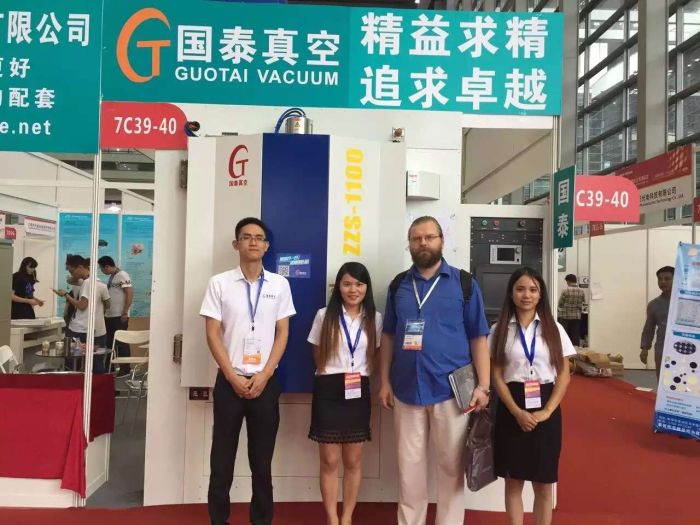

Customer visit

Exhibition

Certification

Package show

Note:

1.We have more optical vacuum coating machine models,such as ZZS500,ZZS630,ZZS800,ZZS900,ZZS1100,ZZS1300,ZZS1600,ZZS1800,ZZS2000,ZZS2350.

2.Equipment final size and configuration customized production according to your requirements.